Amazone UF2002 Sprayer Installation and Calibration | Precision Farming in Action

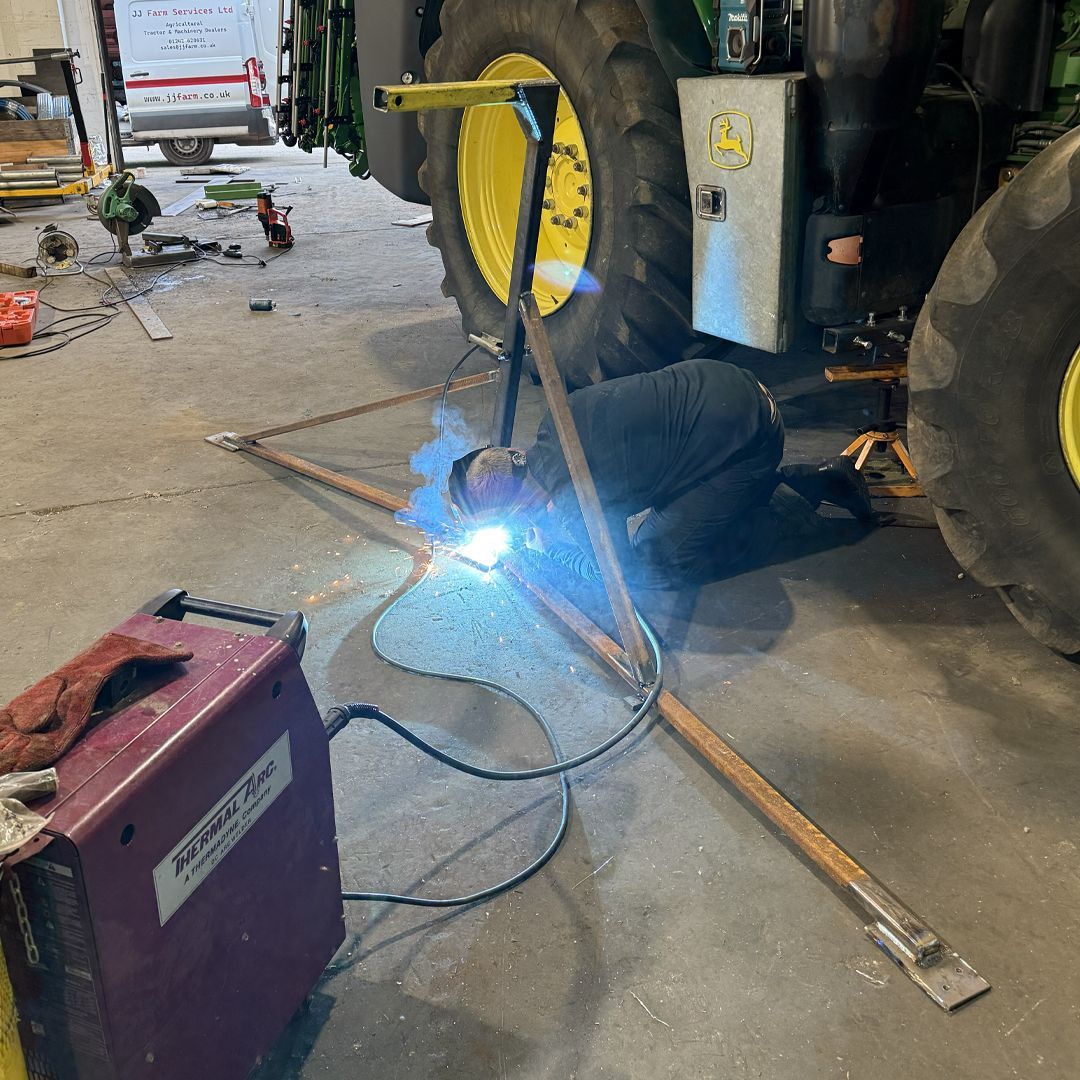

We recently completed the installation of a new Amazone UF2002 sprayer paired with an FT1502 front tank for one of our customers here in the UK.

As part of our service, our technicians carried out a full on-farm setup and calibration, using water to fine-tune the system before fieldwork began. This ensures every machine we install is fully operational and ready to deliver precise, efficient spraying from day one.

Precision and Control for Modern Farming

The Amazone UF2002 is designed with precision farming in mind. Equipped with individual nozzle control, it minimises overlap and chemical waste, ensuring products are applied exactly where they’re needed. This not only saves money on inputs but also promotes more sustainable and environmentally friendly farming practices.

Its advanced ContourControl boom technology automatically reacts to undulating terrain, maintaining the ideal nozzle height for even spray coverage across the entire working width. The result? Greater accuracy, reduced drift, and consistent performance — key factors for precision agriculture.

When paired with GPS section control, the UF2002 integrates seamlessly into precision farming systems, giving operators greater control, improved traceability, and more efficient field management.

Enhanced Capacity and Stability with the FT1502

Adding the Amazone FT1502 front tank increases the total spray capacity and improves weight distribution across the tractor, enhancing driving stability and reducing soil compaction. The extra capacity allows operators to cover more hectares between refills, saving time and boosting productivity during busy spraying windows.

Set Up, Calibrated, and Ready for the Field

After thorough setup and calibration, this Amazone sprayer was ready to go — delivering precision, reliability, and performance straight out of the yard.

If you’re looking to upgrade your spraying system or explore Amazone precision farming equipment, our team can help you find the right setup for your farm.

📞 Get in touch today to learn more about the Amazone UF2002, FT1502 front tank, or our on-farm installation and calibration services.

More latest news…