Giving a Classic Workhorse a New Lease of Life

We see all kinds of tractors come through the workshop, from the newest models to the true classics that have earned their keep many times over. One of those classics is the Massey Ferguson 390, a real favourite on many farms for its simplicity, reliability, and no-nonsense power.

We recently had a customer’s MF 390 in for clutch issues, but, as often happens with older machines, the visit turned into much more worthwhile preventive maintenance.

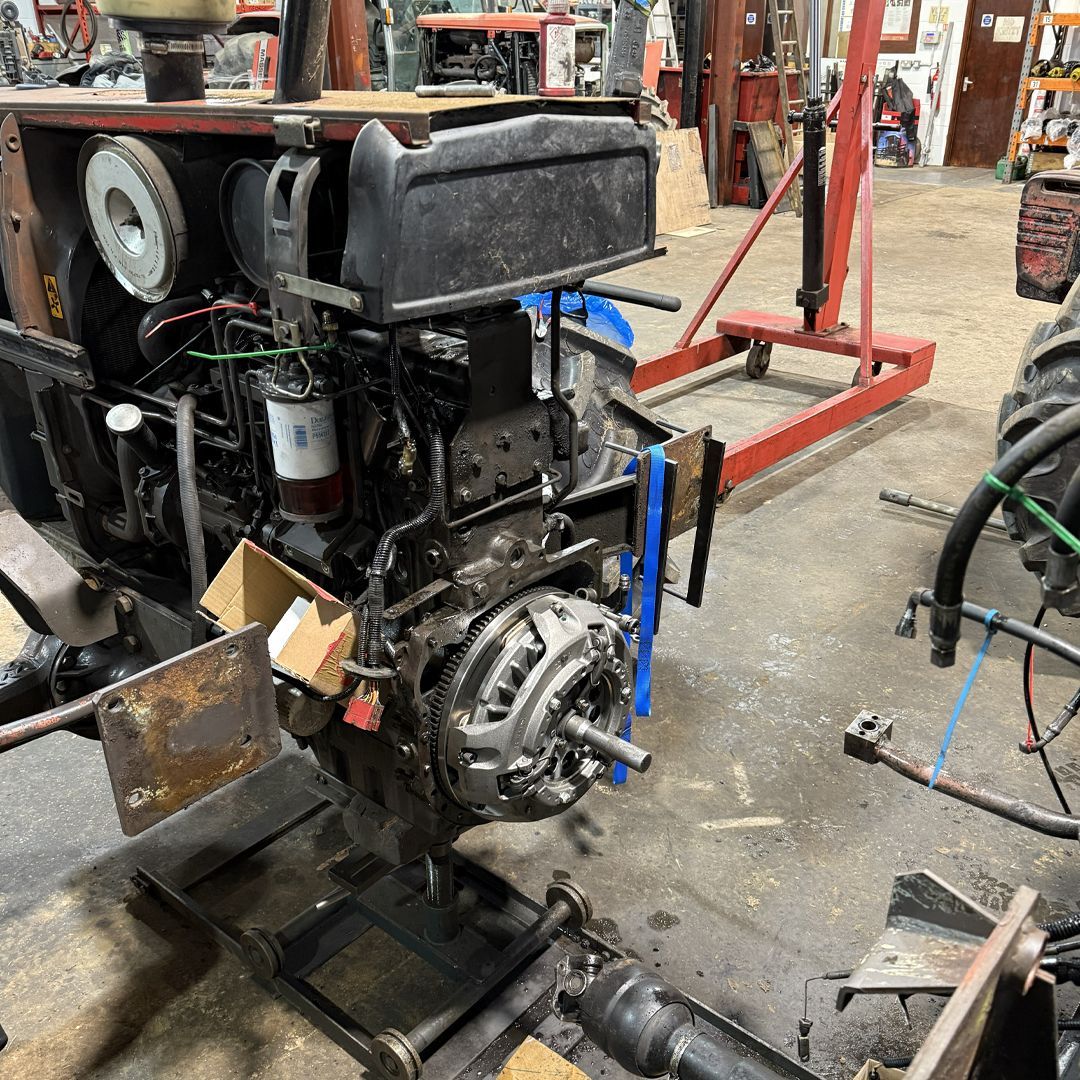

Clutch Replacement

The tractor was struggling to engage properly, so our first job was to fit a new 13" clutch plate, along with a new flywheel, and fresh clutch bearings and bearing carrier.

These parts are essential for smooth operation, especially on a machine that handles daily, heavy farm work.

Replacing these components ensures:

- Smoother gear changes

- Improved pulling power

- Reduced wear on the transmission

- More years of reliable use

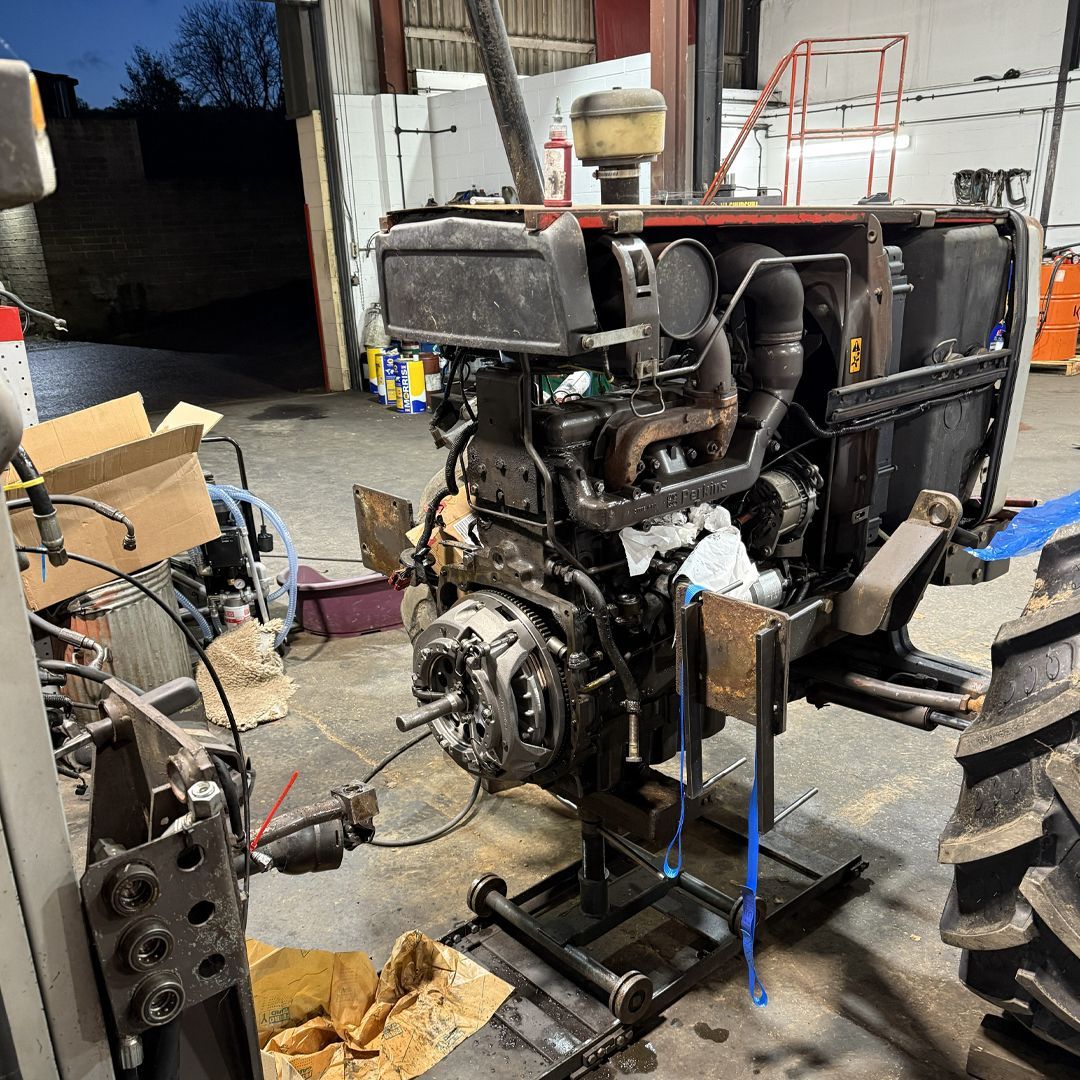

Fuel Pump Replacement

While it was in the workshop, we noticed the fuel pump was leaking diesel — a common issue on older tractors.

To prevent:

- Wasted fuel

- Contamination

- Potential fire hazards

- Inconsistent engine performance

The pump had been on there for a few thousand hours, so the best thing to do is to fit a brand new fuel pump, solving the leak and improving running quality at the same time.

Full Engine Service

With the tractor already split and on the ramp, this was the perfect opportunity to carry out a full engine service.

We fitted:

- Fresh engine oil

- New oil filter

- New fuel filter

Routine servicing is one of the best ways to extend the life of older tractors, keeping them dependable through every season.

A True Workhorse

The Massey Ferguson 390 may be getting on in years, but with the right care it will continue working hard for many more to come. Jobs like this are a reminder of why so many farmers still rely on these classic tractors, simple, strong, and built to last.

If your tractor needs repairs, servicing, or a bit of TLC, the team at JJ Farm Services is here to help.

📞 Get in touch to book your machine into the workshop.

More latest news…